timed out / Products / Personal armorum tutela / PROMPTU Coverall

-

PP + PE Non texta Material PROMPTU Coverall Cum Tape TTK-A01

PROMPTU Coverall Cum Tape

-

-2-1.png)

PET + PE Non texta Material PROMPTU Coverall Cum Tape TTK-A01

PROMPTU Coverall Cum Tape

-

TEXTUS Material + PTFE Membranae Disposable Coverall Cum Tape TTK-A03

PROMPTU Coverall Cum Tape

-

Materiam texta + PTFE Membrana + Tricot Disposable Coverall Cum Tape TTK-A04

PROMPTU Coverall Cum Tape

-

-5.png)

Materiam texta + Obice membrana membrana + Tricot Disposable Coverall Cum Tape TTK-A04

PROMPTU Coverall Cum Tape

-

210TWoven Coating Protective Material-hyacintho PROMPTU Coverall Sine Tape TTK- B01

PROMPTU Coverall Sine Tape

-

.png)

210TWoven Coating Protective Material-album PROMPTU Coverall Sine Tape TTK- B01

PROMPTU Coverall Sine Tape

-

SMS Non texta Material PROMPTU Coverall Sine Tape TTK-B02

PROMPTU Coverall Sine Tape

-

-1.png)

PP+PE Non-texta Materia PROMPTU Coverall Sine Tape TTK-B03

PROMPTU Coverall Sine Tape

-

PP Non texta Material + Obice membrana membrana PROMPTU Coverall Cum Tape TTK-A01

PROMPTU Coverall Cum Tape

-

PET+PE Non texta Material PROMPTU Coverall Sine Tape TTK-B03

PROMPTU Coverall Sine Tape

Wujiang TTK®

Textile&Finishing

Co., Ltd.

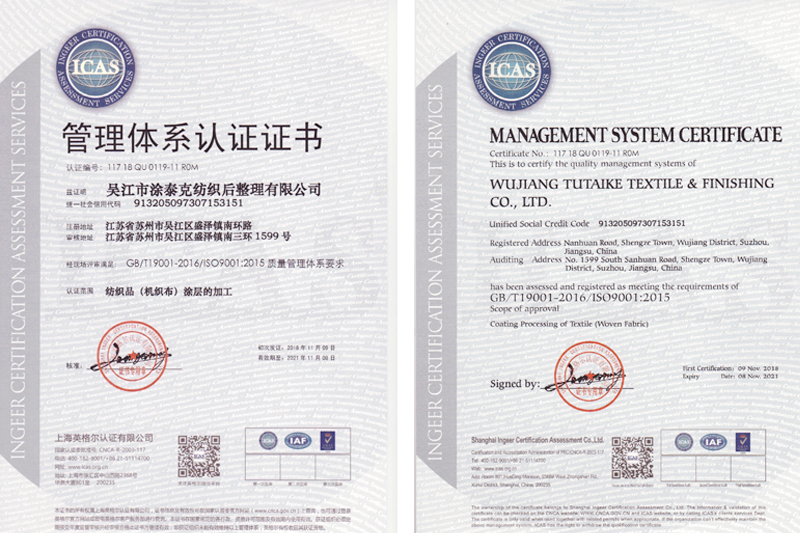

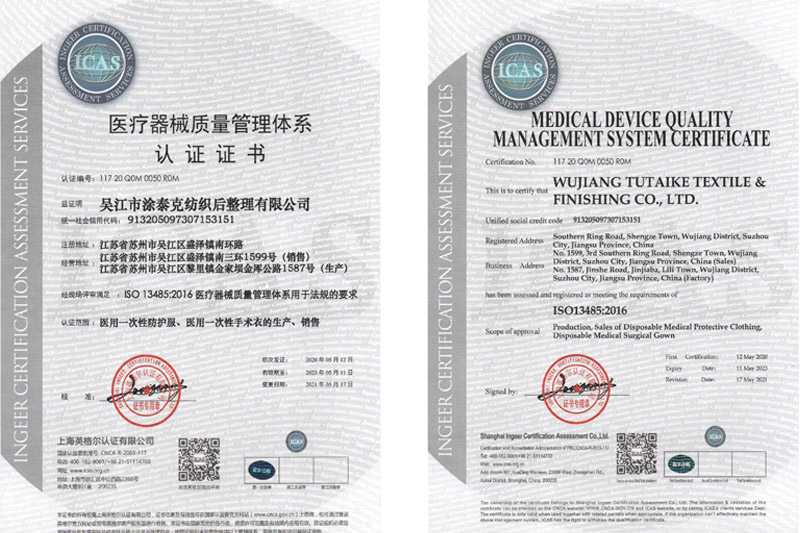

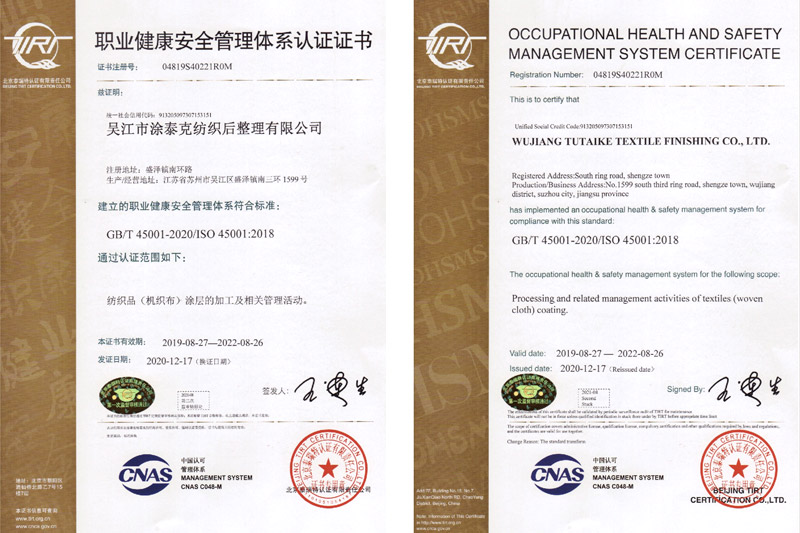

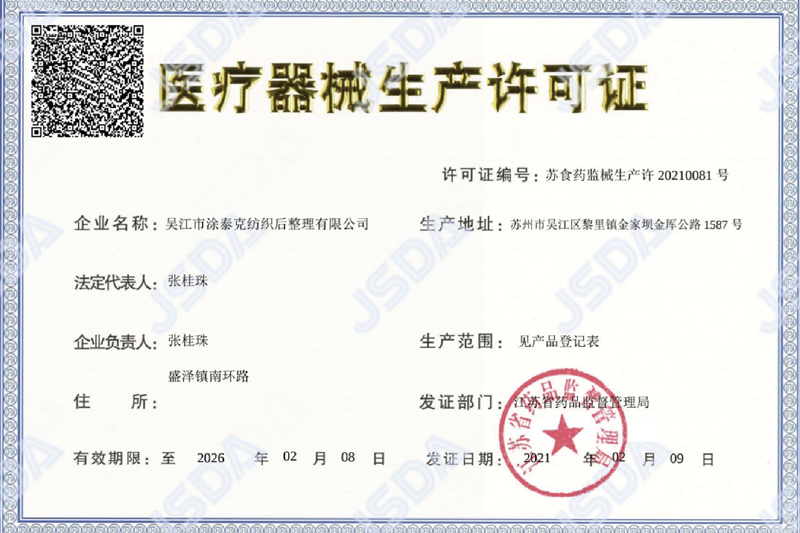

Wujiang TTK@ Textile&Finishing Co., Ltd sit amet Sinis protection suit manufacturers et non solum togae chirurgicam officinam, transiens ISO9001: 200 qualitas administrationis systematis SGS certificata est. Societas fabricae texendi officinas, officinas efficiens, officinas, laminas et compages officinas, translatio vestis et cylindrus tractor membrana summus finis membranas officinas et officinas typographicas sibi subordinatas habet. Societas etiam suum commercium Dept habet..

-

Nostra professio Consuetudinem tutela gow, Societas fabricae texendi officinas, officinas efficiens, officinas, laminationem et compagem officinam habet, translatio vestis et tractor cylindrus efficiens membranam summum finem officinam et officinam typographicam sibi subordinatam. Societas etiam suum commercium habet Dept., Sample Dept., Investigationis et Inquisitionis Progressus Dept. et Test Centrum, quod unum sistendum servitium formans pro textilibus productis.

TTK est investigatio & progressus inceptis quae in functionibus anti-microbialibus pro 2 decenniis versatus est. Initium fuit investigationi et evolutioni fabricarum militarium altarum, antibacterial materiae medicinae et fabricarum civilium functionis. -

Anno 2003, societas in supplementum rudium textilium ministravit et bona complevit ad lites in pugnando SARS adhibita, et inde ex quo unam ex suis materias medicinae altas technicas spectavit. directiones ad inquisitionem & progressionem. Respectu COVID-19 praevalente, inceptum quam primum elaboravit fabricae materiae non textae + PE membranam antibacterial valde amet compositam productam) aptam ad dispositionem medicinae rectae productionis tutelae aptae et productionis novarum disponibilis ad sectam medicinae tutelam ordinatam. facta de TTK-PE arbitrio altiore toga. Novus productus praestare potest antibacterial perficientur et respirabilitatem sectae tutelae et altae vires fabricae non textae.

-

Explore more

Nos inceptis textilibus fabricandis maxime versamur in venditionibus et fabricandis confectis textilibus, cum auto-currendo importare et exportare ius, transeuntes ISO9001:200 systema qualitatis administrationis per SGS certificatum.

-

Officina normatum

ISO9001 2008 Industria normatum et magnae capacitatis machinae accessoriae artifices, qualitas clientium praestatur et tempus traditio clientium praestatur.

-

Urbanus Equipment

Internationalis instrumenti processus urbani, superioris facultatis consilia, et exquisita technologiae fabricandi, clientium certitudinem quolibet tempore prosequens.

-

Lab Usus

Societas progressum laboratorium ad experientiam in-situm pro clientibus dubitantibus praebet, te sine paenitentiis electionem facere sinit.

-

Fortis Service Team

Ut faciliorem redderet venditionem, venditionem et post-venditionem servitii clientium per patriam, societas turmas professionales statuit, ubicumque es, parte tua sumus!

-

-1.png) Industria News

Industria NewsQuid facit SMS nonwoven ensure in tutela effectum de Sexto togis post disinfection?

Medical Donec missionibus, SMS nonwoven anti-virus primi-gradu Stringa togis aedificare salute obice pro medical virgam cum suis perficientur. Quar

-

Industria News

Industria NewsUt non-textilia textilia et seamless tapes aedificare fortis anti-virus defensionem linea pro visitor tunicas?

In medical environments, in periculo virus transmissio semper existit. Ut an maximus tutela apparatu, in anti-virus perficientur medicinae disposue

-

Industria News

Industria NewsQuid est Lightweight Solatus Anti-Virus IMPERVIUS Primo-Level Stringa Togenta Waterproof?

In Medical Cura et Epidemiam praeventionis opus, quod momenti de Lightweight Solatus Anti-Virus IMPERVIUS Primo-Level Stringa togis nutrientibus to

-

Industria News

Industria NewsQuid est Watplproof SMS nonwoven fabricae effective defendat contra virus tumultus?

In agro medicinae praesidium, IMPERVIUS SMS nonwoven anti-virus tres-campester ultricies togis habere vitalis missionem, et core anti-virus mechani

-

Industria News

Industria NewsQuid facit Nano-coating amplio tutela perficientur medicinae transparent tutela personas?

In agro medicinae tutela, medicinae transparent tutela personas sunt clavem linea defensionis ad obstructionum droplets et aerosols, et perficientu